Design Center & Mold Shop

New Technologies

Our engineers work hard to create the most cost-effective design for your part by utilizing the latest technology.

With our innovative 3D CAD software we optimize the moldability of your part, and continue to improve your part, even after production has begun.

Tooling Department

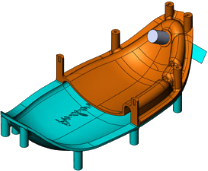

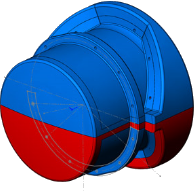

Our tooling department is built on dedication to quality assurance. Whether you need molded foam or a rotationally molded part, we provide high quality prototype tooling and final production tooling. This core competency allows our customers, and Roto Plastics, an advanced level of control over rotomolding and molded foam projects.

An important factor in our joint success is Roto Plastics' Scheduled Maintenance Program, which prolongs the life of our customers' tooling. As part of our integrated systems approach to rotomolding and foam molding, we evaluate each tool before storing it for future use. You can be sure that Roto Plastics is dedicated to bringing you only the best in tooling development and customer satisfaction.

Let's Get Started

Contact us now to learn how our design and tooling capabilities can improve your molded foam or rotationally molded part.